Our Capabilities

Custom product design

Along side our core range of products we are often asked to product one off or small batch custom items.

These special projects allow us to create bespoke products for the end user almost on a mission by mission basis. Such was the success of early custom projects we now offer full in-house design, 3D printing and manufacturing capability.

This service has allowed us to develop unparalleled relationships with Special Forces units, Counter Terrorism Police units and other government agencies from around the world by offering solutions to meet their requirements.

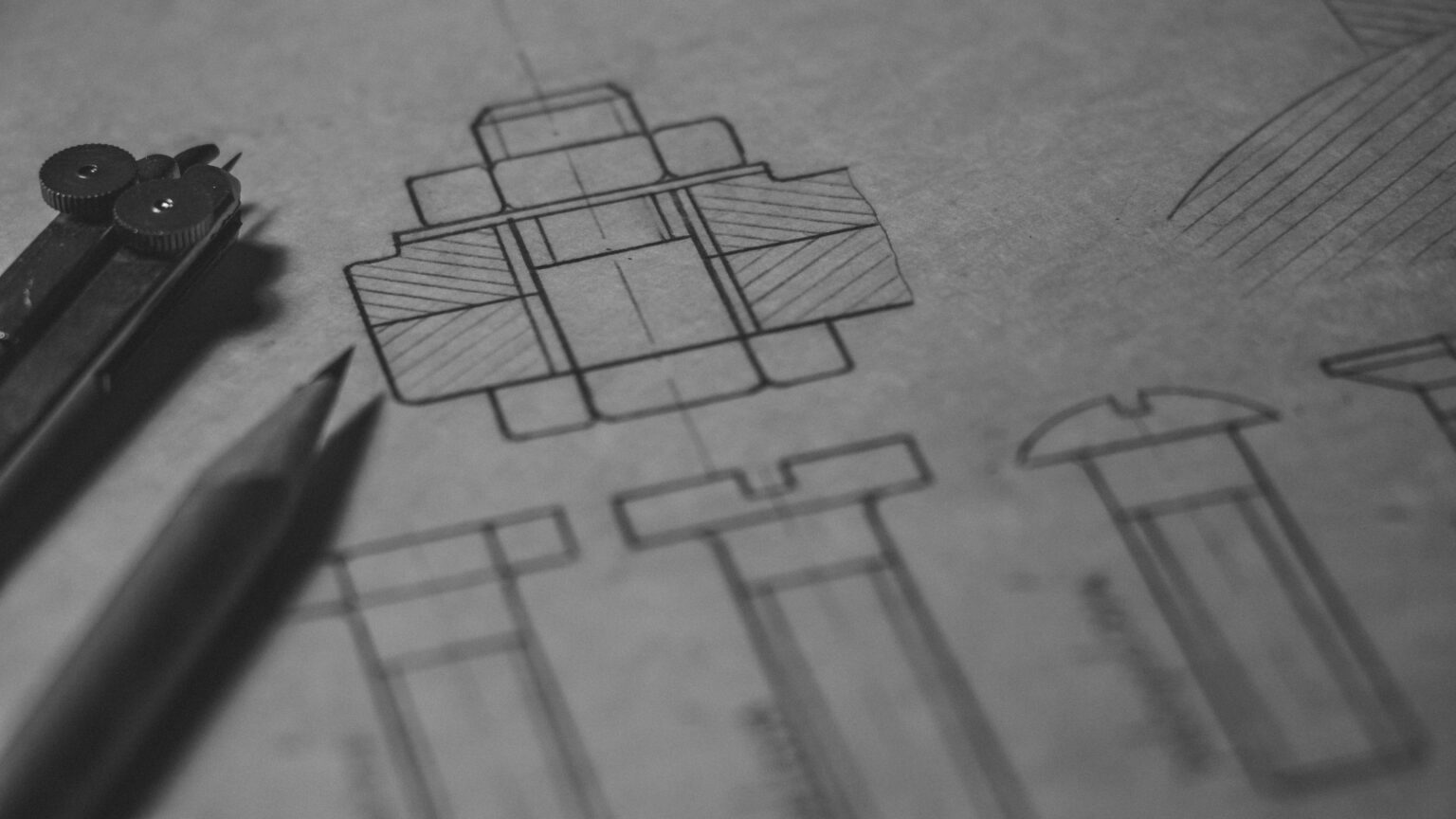

The Design process

Our dedicated design team can manage all aspects of a project from the initial concept stage, to producing initial drawings and 3D assembly designs for approval to ensure the project meets the requirements.

We will then then 3D print pre-production models in order to visualise the designs from the conceptual stage. This allows for components to be produced to verify the design and allow for amendments before final production.

Once the designed has been confirmed we will produced the product to the finished specified using our in house machining capabilities.

To discuss your requirements please get in touch.

Machining Capabilities

We can provide complete solutions from conception through to final production utilising a range of materials and manufacturing processes including:

Materials

- Titanium

- Stainless Steel

- Aluminium

- Mild Steel

- Carbon Composites

- Polymers

Methods of manufacture

- Multi Axis CNC Milling and Turning

- Extrusion

- Fabrication

- Casting

- Welding Laser Cutting

- Roll Wrapping

Post-machining and finishing options

- Chemi-Blacking

- Galvanising

- Shot blasting

- Anodising

- Powder Coating

- Plating

- Grinding

- Deburring